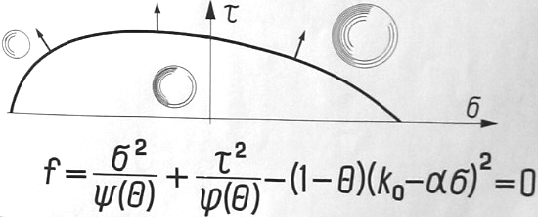

Proposing a loading function for porous and powder materials with structurally- inhomogeneous structure. Depending on model parameters and the value of porosity, the trace of the plasticity surface corresponding to this loading function can vary from an ellipse (shifted in the negative direction of the hydrostatic stress axis) to a curve like an axial cross-section of an egg.

The physical reason for the nonsymmetry of the trace with respect to the origin is the impossibility of a complete adaptation of structural elements of the material when they are deformed jointly. The consistutive relations based on the proposed loading functions and gradient conditions, give a unified framework to study pressure deformation of compact and noncompact (powder and porous) materials and to describe a number of experimentally observed physical effects, most notably:

- the emergence, growth, and healing of pores under plastic deformation;

- the inherent unremovable porosity under all-round compressing of porous and powder material when the leading deformation mechanism does not change;

- the presence of the stationary porosity under proportional loading under pressure;

- the increase of material stability type under pressure;

- the increase in ductility under pressure (in particular, the presence of the brittle-ductile transition in hard to deform materials).

Related publications:

Y. Beygelzimer. Constitutive Equations of a Porous Body with a Structurally-Inhomogeneous Matrix, Proceedings of International Workshop on Modelling of Metal Powder Forming Processes, Grenoble, France, July 21--23, 1997, pp. 57--67.

Y. Beygelzimer, B. Efros, V. Varyukhin, A. Khokhlov. A continuum model of a structurally-inhomogeneous porous body and its application for the study of stability and viscous fracture of materials deformed under pressure. Engineering Fracture Mechanics, Vol. 48, No. 5, pp. 629--640 (1994).

Y. Beigelzimer, A. Getmansky, L. Alistratov. Plasticity Conditions for Powders of Solid-Alloy Mixtures, Poroshk. Metall (in Russian), No. 12, pp. 11--15 (1986)